Training

Within

Industry

(TWI)

Build Workforce Stability & Skills

At Operational Excellence Consulting, our Training Within Industry (TWI) programs equip supervisors and frontline leaders with proven tools: Job Instruction, Job Methods, and Job Relations. We help you reduce rework, improve quality, and strengthen team performance through structured, experiential learning.

What is TWI?

Origin & Relevance

TWI (Training Within Industry) was developed in the U.S. and later adopted in Japan in the 1950s. It’s foundational in Lean methodology, shaping practices in companies such as Toyota.

Core Components – JI, JM & JR

Job Instruction (JI): Teach employees to do jobs correctly, safely, and consistently.

Job Methods (JM): Improve how work is done—streamline workflows, reduce unnecessary steps, and optimize current resources.

Job Relations (JR): Equip supervisors to build trust, resolve conflict, and lead people well.

Additional Component - Job Safety (JS): Teach supervisors to analyze the causes of accidents and eliminating them before they happen.

Why TWI Matters

Build Stability & Consistency

TWI standardises how supervisors teach, coach, and lead—reducing variation and reinforcing quality.

Improve Productivity & Quality

Companies using TWI have reported large gains: reduced training times, less scrap, fewer labor hours, and higher output.

Strengthen Supervisory Capability & Labor Relations

The programs enhance supervisor skills, improve relations with teams, and support a culture of continuous improvement.

Client Success Stories

.jpeg)

WORKSHOP HIGHLIGHT

Building Frontline Leaders: How Grundfos Is Leveraging TWI Skills AI Can’t Replace

August 07, 2025

WORKSHOP HIGHLIGHT

August 13, 2015

Learn how to apply the TWI Training Programs (JI, JM & JR) to improve workplace productivity, quality and safety.

Learn how to instruct employees so they can quickly remember to do a job, correctly, safely and conscientiously.

Learn how to improve methods for producing greater quantities of good quality products in less time by effective use of current resources.

Learn how to lead employees so that problems are prevented and analytical methods are used to effectively resolve problems.

Prefer complete TWI presentation toolkits?

Choose the Core TWI Programs Bundle (JI, JM & JR) or the Complete TWI Framework Toolkit (5 Programs).

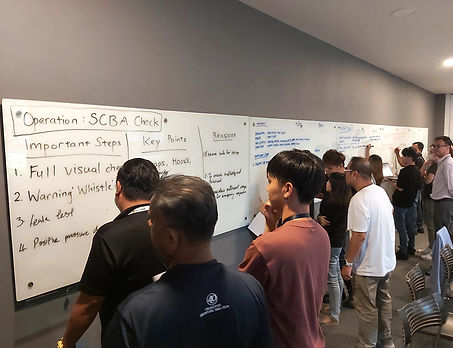

Our TWI Workshops Around the Region

TWI workshop (JI, JM & JR)

in Singapore

TWI Job Instruction workshop

in Ho Chi Minh City, Vietnam

TWI workshop (JI, JM & JR)

in Kep, Cambodia

TWI Train-the-Trainer program

(JI, JM & JR) in Singapore

TWI workshop (JI, JM & JR)

in Manila, Philippines

TWI Job Instruction workshop in Singapore