top of page

Standard Work: How to Create Consistent and Efficient Operations

Allan Ung “Where there is no standard, there can be no Kaizen.”

Taiichi Ohno Introduction In the world of manufacturing, standardization is a crucial factor that determines the success or failure of an organization. Standard work , in particular, is an important tool that enables manufacturers to create a consistent, repeatable process that meets the customer's needs while minimizing waste. In this blog post, we will explore the concept of standard work, its benefits, prer

Allan Ung

Apr 2, 20237 min read

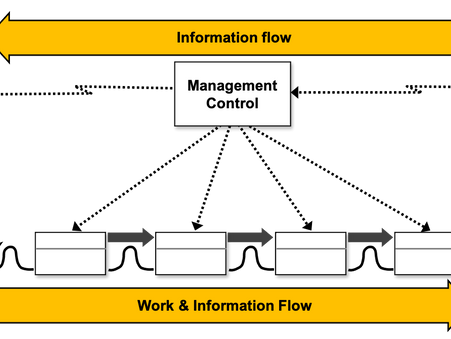

Value Stream Mapping: How to Transform Business Processes for Peak Performance

Allan Ung Introduction In today's fast-paced business environment, organizations face many challenges, including intra-organizational conflict, operational waste, and disconnects in how work gets done. To address these issues and achieve outstanding performance, organizations need to implement effective methodologies to visualize and resolve these problems. Value Stream Mapping is a proven approach that enables organizations to identify and eliminate inefficiencies, redundan

Allan Ung

Mar 30, 20236 min read

Gemba Walk Insights: What Leaders Can Learn from the Front Lines

Allan Ung “Genchi Genbutsu [go and see the actual situation] means imagining what you are observing is your own job, rather than somebody else’s problem, and making efforts to improve it.” Akio Toyoda What is Gemba Walk? The Gemba Walk is a powerful Lean management tool that has its origins in Toyota's manufacturing processes. Gemba refers to the actual place where value is created, and a Gemba Walk involves leaders visiting the front lines to gain first-hand knowledge of ho

Allan Ung

Mar 30, 20235 min read

Root Cause Analysis: The Key to Solving Problems Permanently

Allan Ung “When we fail to grasp the systemic source of problems, we are left to "push on" symptoms rather than eliminate underlying causes.” Peter Senge Root Cause Analysis (RCA) is an essential tool for organizations to solve problems effectively. It is a systematic approach that involves a set of methods and techniques to identify the underlying cause of an issue or problem, rather than just treating the symptoms. The main goal of RCA is to prevent the problem from happen

Allan Ung

Mar 30, 20234 min read

8 Steps to Mastering 5S Implementation in Your Workplace

In this blog, we will discuss the eight steps of 5S implementation, from forming a steering committee to conducting 5S audits, and how they can be applied to achieve successful implementation of 5S in any organization.

Allan Ung

Mar 29, 20234 min read

Lean Daily Management System (LDMS): A Winning Strategy for Operational Excellence

Allan Ung Updated on March 09, 2024 Implementing LDMS transforms daily operations, driving excellence at every level. "The role of leadership in a lean organization is to create an environment where problems are openly acknowledged and addressed, and where continuous improvement is the norm." David Mann Author of "Creating a Lean Culture" Introduction In today's competitive market, organizations are constantly looking for ways to improve their efficiency and productivity whil

Allan Ung

Mar 26, 20235 min read

Design Thinking: The Cyclical Process That Fuels Innovation

Allan Ung "Design is not what is looks like or feels like. Design is how it works." Steve Jobs Introduction Design thinking is a problem-solving approach that is becoming increasingly popular across various industries. It is a user-centric approach that involves understanding the needs, wants, and behaviors of users to create innovative solutions that are both practical and feasible. Design thinking is not just limited to the field of design; it can be applied to any proble

Allan Ung

Feb 25, 20234 min read

Streamlining Your Workplace: The Power of 5S Principles

Allan Ung "Good workplaces develop beginning with the 5S's. Bad workplaces fall apart beginning with the 5S's.”

Dr. Hiroyuki Hirano In a world where organizations seek heightened competitiveness, the widespread adoption of Lean principles is becoming a norm. A comprehensive strategy demands the seamless integration of office activities with manufacturing operations to eradicate waste, a crucial step in boosting productivity. Regardless of nomenclature, the office operates a

Allan Ung

Jun 30, 20163 min read

Becoming Lean: How to Eliminate Waste and Stay Competitive

by Allan Ung Recession or boom, companies need to sharpen their competitive edge by applying Lean Management principles to cost reduction - that is, the elimination of non-value-added activities or waste from the value stream processes. Be Lean In the Lean Management philosophy, all activities in an organization are grouped into two categories: 1. Value-added (VA) activities, and 2. Non-value-added (NVA) activities. In the context of Lean Management, VA and NVA activities

Allan Ung

Jun 29, 20164 min read

bottom of page